News & Articles

GUEST BLOG - AN UPDATE ON TOY SAFETY BY BEST YEARS

U

As a toy manufacturer it is our responsibility that everytoy we offer to the marketplace is safe and fit for purpose.

So first thing any manufacturer needs to know is what is atoy?

A toy is classified as a product designed or intended for use in play bychildren under 14 years of age. Play does not have to be the exclusive use ofthe product, so something like a soft toy keychain is also covered because ithas a secondary play value. If a product has been designed to have “kid appeal”whatever its primary use, it must also be tested as a toy.

Everything we sell is designed and manufactured to be a toyso this isn’t an issue for us but it does have a big impact on companies which,for instance make toys in the shape of food, or gift food or keychains who nowhave to ensure their products comply not just to things like food standards butalso toy safety as well.

The legislation we follow at the moment is the The European Toy Safety Directive. Ironically this is not legally binding in itself, it only becomes legal if its implemented in parliament by the country, which it has in the UK. On a top line level the directive basically says that a toy must be safe, it must have no sharp edges, no harmful chemicals and no small parts.

EN71 then applies harmonised standards (EN71) to these directives which then makes it legal. If a toy manufacturer has applied these standards to the design and manufacture of their toys they will print the CE logo on the label to show that the toy complies.

Toys must satisfy the essential safety requirements of the Toy Safety Directive – there are 2 ways now that this can be done – one is going down the testing route through test houses. The other is self certification.

On the face of it self certification could sound as if its just a case of saying “Yup. Our toys are safe” but actually it is a lot harder than just testing a single item off the production line.

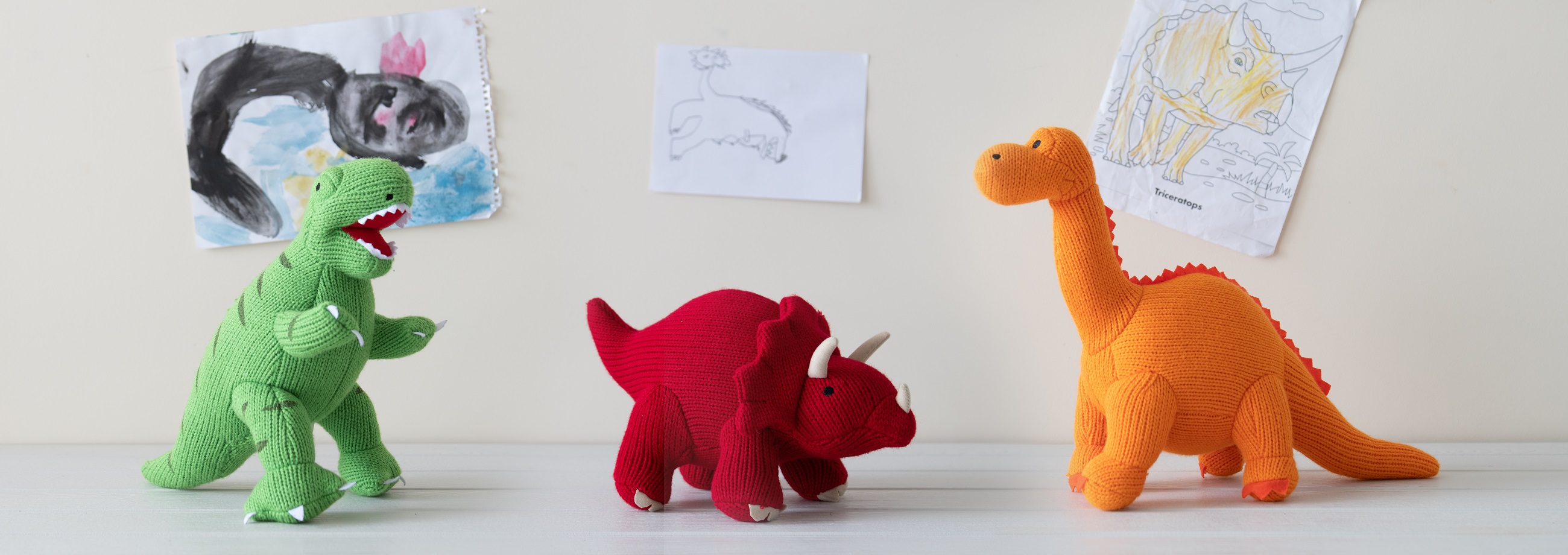

At Best Years we have a very stable supply chain. Rather than chasing around the Far East to get the cheapest prices we have always worked with the same people going back years and years. This means that we are able to get documentation to trace the yarn we use and any other materials all the way back to the original source. This includes the dyes we use, the cotton for the crochet, the material for our knitted dinosaurs and even the thread we use for the embroidered eyes.

Because we have such a close relationship with all our suppliers we can prove that the toy has been designed to be safe, the materials used to make the toy are safe and the way that it has been made ensures it is safe. This is the process called Self Certification. It moves the emphasis on safety away from a

We’ve been working with most of our suppliers for over 10years and have a good working knowledge of all the requirements so for us itspretty straight forward. However it requires both an in depth knowledge of toysafety and your supply chain plus an awful lot of paperwork to back the wholeprocess up

Our knitted and crochet toys are all designed andmanufactured to be suitable for children from birth, which means that we ensurethat there are no small part such as plastic eyes, obviously no sharp edges andthat the toys can be washed by immersing them in water. You still see some toyswhich say “surface wash only” but to comply with safety regulations all softtoys must be able to be washed by being totally immersed in water. Anyone whohas seen a child chewing vigorously on a toy and then wiping his left over foodon it will understand the reason for that rule!

Toy safety is continually evolving and changing as newchallenges, new processes and new toys are introduced. In order to ensure thatwe keep up to date with these changes we attend seminars by people such as BureauVeritas, an accredited test house.

Last week we attendedone such toy safety seminar last week. The chap who took the seminar has beenin toy safety for over 42 years and he has seen many, many changes in his time!He has also seen lots of toy manufacturers being fined for toy safety issuesincluding some very big fines but its important for both consumers andmanufacturers to know that people producing poor quality toys are being caughtand then pay the price for poor product development.

One of the key issues which challenge many toy makers arethe use of chemicals. We now have so much more information about which chemicalsare harmful and which are safe than ever before. This has been one of thebiggest changes to EN71 in the past few years.

Before accepting dusted down toys for your baby from your kind neighbour’sattic do remember that toy safety evolves and things which were once deemed tobe safe would now be banned. There was a toy placed on the market in the 1950sthat had actual uranium ore in it! Supposedly it was an educational toy but itsnot something which would be allowed to be sold today.

And did you know that the green arms on an alarm clock used to be mildlyradioactive…

A big change to the regulations over the last couple ofyears is all the paperwork that needs to be held for each product. There aredifferent processes which need to be followed by manufacturers, distributorsand retailers but all of them require paperwork to be held to prove thatprocesses have been followed

1. As a manufacturer we must ensure that the toy complieswith essential safety requirements. Technical files, safety assessments,declarations of conformity are all part of the paperwork now required for eachtoy. We also need to ensure that each toy has our address, a batch code (fortraceability), a product code and the CE mark.

2. As an importer/distributor we must ensure that themanufacturer has all the relevant paperwork and that the product has our nameand address on it.

3. If you are a retailer it is important to note you alsoneed to ensure that your supplier has the relevant paperwork available. Youalso need to ensure that your storage conditions and any transport you use (ieif you send the toy to someone) do not jeopardise the toy’s compliance.

Everyone in the chain has a responsibility to ensure theproduct that ends up on the shelf and is bought by a customer is safe.

A few bite size bits of info:

Decorative objects for festivities and celebrations are notclassed as toys – therefore they do not need a warning on them. The age warning is only used when the productis classed as a toy.

All pen lids now should have air ventilation in the cap –have a look at the pen you’re using…does it have one? This air ventilation willallow the person to breathe if its accidently swallowed.

Warning on toys. Because any warning on the toy is deemed todetermine the decision on the purchase of a toy (if you are buying somethingfor a baby you need to know that it is suitable from birth) the warning must bevisible to the consumer at point of purchase. This is especially important ifyou are selling on line. Your product description must include any safetynotices or information.

There were a couple of big toy issues for toy manufacturersand for test houses in 2018.

- Slime –The issue was that how do you defineslime. Is it a solid or is it a liquid as it comes in both forms and thereforecould be tested in one of two ways. Since slime includes chemicals TradingStandards verged on the side of caution which generated a lot of negative pressas products had to be recalled.

- Squishies – these caused a major headache withregards to age grading and several countries in the EU have banned them. Theyare made from specialised rubberised foam and many have scent added to makethem more attractive, ie if the squishy is designed to look like a water melon,then a scent of water melon was also added. The trouble was that the foam canbe picked off by little fingers and given it smells so delicious the foamquickly ended up in the mouth and was swallowed.

There were warnings that the chemicals used to make the toys included somewhich were toxic and should not be ingested. Furthermore because children aremore sensitive to chemicals that adults then continued exposure to thechemicals used in the squishy could be harmful.

Both of these toys had passed testwhen first designed and manufactured it was only as they became more popularthat they were subjected to closer scrutiny and issues identified.

So what safety issues are we looking out for in 2019?

Smart Toys - The Government is considering regulatingconnected toys with regard to personal information. These are toys which aredesigned to connect to the internet to gibe the child an interactive experience.These “smart toys” have microphones,they have cameras and they even have recording devices. All these things storedata obtained from the child and usually it is then stored in the cloud. At themoment there is no toy safety regulations as to what can be stored, for howlong and where it should be stored. Given that data such as your child’s name,age, date of birth and sometimes even address are normally stored it makessense that there should be some parameters around this issue.

Sequin plush – over the last year there has been a surge of soft toys released which are partially or completely covered in sequins. There is no doubt that these toys are attractive to children under 3 but manufacturers have been labelling them as suitable for 3+. Labelling a sequin covered soft toy as 3+ meant that the sequins did not have to pass the test for small parts (ie be small enough to swallow safely or secured on to the toy in such a way as to ensure that they could not be detached)

You can find out more about Gaynor and Best Years here